Silicone O-Rings, Seals & Gaskets

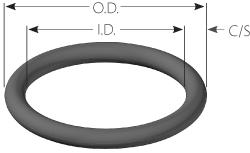

We offer silicone o-rings in all standard sizes, as well as silicone seals and gaskets in custom configurations that are tailored to your specific needs. We can provide custom silicone o-rings, gaskets, and seals with the hardness, colors, and industry certifications your application requires.

Order your AS568 standard O-rings today, or contact us to discuss your custom requirements.

Silicone O-Ring Products

We offer silicone o-rings in all standard sizes, as well as silicone seals and gaskets in custom configurations that are tailored to your specific needs. We can provide custom silicone o-rings, gaskets, and seals with the hardness, colors, and industry certifications your application requires.

Order your AS568 standard O-rings today, or contact us to discuss your custom requirements.

Characteristics of Silicone Rubber O-Rings, Seals & Gaskets

Our silicone products are high-quaily, manufactured to withstand demanding environments.

- Resistant to: extreme temperatures, fungal growth, UV and ozone exposure, and weathering

- Not for use with: fuels, silicone and petroleum based oils, acids

- Temperature range: -75° to 450°F (-60°C to 232°C)

- Hardness range: 30 to 80 durometer Shore A

- Standard hardness: 70 durometer Shore A

- Standard colors: rust/orange, translucent; custom colors available—contact us to discuss your color requirements

Silicone Chemical Compatibility & Characteristics

If silicone is chemically incompatible with your application, view our chemical compatibility chart to find the right material for your needs.

- Heat resistance: Excellent

- Cold resistance: Excellent

- Ozone resistance: Excellent

- Weather resistance: Excellent

- Set resistance: Good to excellent

- Electrical properties: Good

- Acid resistance: Fair to good

- Chemical resistance: Fair to good

- Oil resistance: Fair to good

- Water steam resistance: Fair to good

- Flame resistance: Fair

- Impermeability: Poor to fair

- Abrasion resistance: Poor

- Dynamic resistance: Poor

- Tear resistance: Poor

- Tensile strength: Poor

What is Silicone? General Properties, Compatibility & More

Silicone is the general name for a family of polymers that includes any synthetic compound consisting of repeating units of siloxane (from which the material’s alternate name, polysiloxane, derives). Siloxane is best described as a chain of alternating silicon and oxygen atoms; carbon and/or hydrogen are frequent additives.

The most common silicone material is silicone rubber. Silicone rubber is generally non-reactive, stable, and resistant to extreme environments. It can be used in temperatures from -75°F to 450°F (-60°C to 232°C) while still maintaining its useful properties. Silicone’s temperature tolerance helps it avoid brittleness in freezing conditions and maintain its dimensional tolerance at extremely high temps.

Thanks to these properties and the ease with which the material can be manufactured and molded, silicone rubber is used commonly used to produce o-rings, seals, and gaskets.

Versatility for Countless Applications

Silicone rubber can also be found in a wide variety of other products, from kitchen utensils to thermal and electrical insulation. It is commonly used in automotive manufacturing, medical devices, food storage products, electronics, home repair and hardware products, and a host of “unseen” applications.

Custom Silicone Approvals

Using specialized compounds and production processes, Ace Seal can create custom silicone o-rings, silicone seals, and silicone gaskets that meet a range of industrial or regulatory standards, including:

- FDA

- 3/A

- Class VI

- UL

- Mil-Spec

High-Performance Silicone Gaskets from Ace Seal

With their ability to withstand temperatures as high as 450°F and as low as -75°F, gaskets made from silicone rubber are highly versatile. You can find these gaskets used in a number of applications, including food processing, medical equipment, automobile engines, aerospace, pharmaceutical, energy, mobile technologies, and more. Silicone gaskets also offer excellent electrical insulation, durability, resistance to high pressures, and are flame retardant. Available in a range of color options, these gaskets are also commonly chosen for their aesthetic value.

Ace Seal can provide you with the high-performance silicone gaskets you need. Contact us today to begin discussing your custom gasket requirements.

Compare & Contrast: Silicone vs. EPDM

Silicone and EPDM are similar in many ways, and the two materials offer a variety of similar characteristics. Both offer good resistance to weathering, UV exposure, and aging, making them suitable for outdoor applications. Silicone and EPDM also exhibit high ozone resistance and an ability to remain flexible in low temperatures.

However, silicone provides far greater high temperature resistance. Unlike EPDM, silicone will maintain its stability and physical properties in temperatures as high as 450°F (232°C). Contact Ace Seal to discuss your application and our expert team will work with you to determine which material is right for your needs.

Contact Us for Silicone O-Rings, Gaskets & Seals

Ace Seal is the name you can count on for high quality standard and custom silicone o-rings, silicone gaskets, and silicone seals. Request a quote today or contact us for more information on silicone materials.